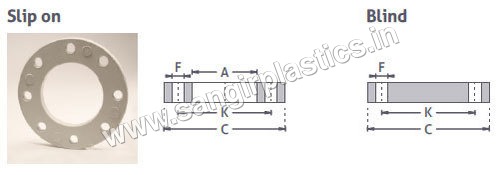

Slip On Backing Flange

Product Details:

- Usage Used for joining loose flanges to pipes

- Features Easy Installation, High Strength, Durable, Precise Construction

- Thread Type N/A (Slip-On, not threaded)

- Dimension (L*W*H) Standard and custom sizes available

- Pressure Ratings PN10, PN16, PN25, or as per requirement

- Pipe Type Suitable for HDPE and PVC Pipes

- Diameter 15mm to 600mm

- Click to view more

Slip On Backing Flange Product Specifications

- N/A (Slip-On, not threaded)

- Easy Installation, High Strength, Durable, Precise Construction

- Used for joining loose flanges to pipes

- PN10, PN16, PN25, or as per requirement

- Standard and custom sizes available

- Suitable for HDPE and PVC Pipes

- 15mm to 600mm

- Carbon Steel, Stainless Steel, Mild Steel, or Ductile Iron

- Flange Fittings

- Slip-On

- Round

- Galvanized, Painted, or Bare

- ASTM A105, AISI 304/316, IS 2062, EN1092

- Up to 25 Bar

- Slip On

- Suitable for high flow pipelines

- Pipeline Joining, Water Supply, Gas Distribution, Industrial Piping

- Yes

- 15mm to 600mm ( to 24)

Product Description

Standard Sizing:

|

ASA 150lbs, ANSI 16.5 |

BS 10 Table D |

DIN 2501 |

||||||||||||

|

A |

K |

C |

F |

Bolt |

A |

K |

C |

F |

Bolt |

A |

K |

C |

F |

Bolt |

|

32 |

60.5 |

90 |

4 X 16 |

M12 |

32 |

67 |

95 |

4 X 14 |

M12 |

28 |

65 |

95 |

4 x 14 |

M12 |

|

37 |

70 |

98 |

4 X 16 |

M12 |

37 |

73 |

100 |

4 X 14 |

M12 |

34 |

75 |

105 |

4 x 14 |

M12 |

|

44 |

79.5 |

108 |

4 X 16 |

M12 |

44 |

83 |

115 |

4 X 14 |

M12 |

42 |

85 |

115 |

4 x 14 |

M12 |

|

52 |

89 |

117 |

4 X 16 |

M12 |

52 |

87 |

120 |

4 X 14 |

M12 |

51 |

100 |

140 |

4 X 18 |

M16 |

|

62 |

98.5 |

127 |

4 X 16 |

M12 |

62 |

98 |

135 |

4 X 14 |

M12 |

62 |

110 |

150 |

4 X 18 |

M16 |

|

78 |

120.5 |

152 |

4 X 20 |

M16 |

78 |

114 |

150 |

4 X 18 |

M16 |

78 |

125 |

165 |

4 X 18 |

M16 |

|

92 |

139.5 |

178 |

4 X 20 |

M16 |

92 |

127 |

165 |

4 X 18 |

M16 |

92 |

145 |

185 |

4 X 18 |

M16 |

|

108 |

152 |

191 |

4 X 20 |

M16 |

108 |

146 |

185 |

4 X 18 |

M16 |

108 |

160 |

200 |

8 X 18 |

M16 |

|

128 |

190.5 |

229 |

8 X 20 |

M16 |

128 |

178 |

215 |

4 X 18 |

M16 |

128 |

180 |

220 |

8 X 18 |

M16 |

|

140 |

216 |

254 |

8 X 23 |

M16 |

140 |

210 |

255 |

8 X 18 |

M16 |

135 |

180 |

220 |

8 X 18 |

M16 |

|

158 |

216 |

254 |

8 X 23 |

M16 |

158 |

210 |

255 |

8 X 18 |

M16 |

158 |

210 |

250 |

8 X 18 |

M16 |

|

178 |

241 |

279 |

8 X 23 |

M20 |

178 |

235 |

280 |

8 X 18 |

M16 |

178 |

240 |

285 |

8 X 23 |

M20 |

|

195 |

241 |

279 |

8 X 23 |

M20 |

195 |

235 |

280 |

8 X 18 |

M16 |

188 |

240 |

285 |

8 X 23 |

M20 |

|

235 |

298.5 |

343 |

8 X 23 |

M20 |

235 |

292 |

335 |

8 X 18 |

M16 |

235 |

295 |

340 |

8 X 23 |

M20 |

|

240 |

298.5 |

343 |

8 X 23 |

M20 |

240 |

292 |

335 |

8 X 18 |

M16 |

238 |

295 |

340 |

8 X 23 |

M20 |

|

290 |

362 |

406 |

12 X 26 |

M24 |

290 |

356 |

405 |

8 X 22 |

M20 |

288 |

350 |

395 |

12 X 23 |

M20 |

|

300 |

362 |

406 |

12X 26 |

M24 |

300 |

356 |

405 |

8 X 22 |

M20 |

294 |

350 |

395 |

12 X 23 |

M20 |

|

345 |

432 |

483 |

12 X 26 |

M24 |

345 |

406 |

455 |

12 X 22 |

M20 |

338 |

400 |

445 |

12 X 23 |

M20 |

|

376 |

476 |

535 |

12 X 29 |

M24 |

376 |

470 |

525 |

12 X 26 |

M24 |

376 |

460 |

505 |

16 X 23 |

M20 |

|

430 |

540 |

600 |

16 X 29 |

M24 |

430 |

521 |

580 |

12 X 26 |

M24 |

430 |

515 |

565 |

16 X 27 |

M24 |

|

480 |

578 |

635 |

16 X 32 |

M30 |

480 |

584 |

640 |

12 X 26 |

M24 |

517 |

565 |

615 |

20 X 27 |

M24 |

|

533 |

635 |

700 |

20 X 32 |

M30 |

533 |

641 |

705 |

12 X 26 |

M24 |

533 |

620 |

670 |

20 X 27 |

M24 |

|

590 |

692 |

749 |

20 X 32 |

M30 |

590 |

699 |

760 |

16 X 30 |

M27 |

618 |

725 |

780 |

20 X 30 |

M27 |

|

660 |

749 |

813 |

20 X 35 |

M30 |

660 |

756 |

825 |

16 X 30 |

M27 |

645 |

725 |

780 |

20 X 30 |

M27 |

Other Information :

- Minimum Order Quantity: 10 Piece(s)

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

Precise Construction & Versatile Application

Designed for rigorous pipeline systems, these slip on backing flanges offer precise construction and high strength, facilitating reliable connections for water supply, gas distribution, and industrial piping. Each unit supports easy installation and is suitable for standard or custom dimensions, ensuring efficiency in both new and retrofit projects.

Durable Materials & Quality Coatings

Manufactured from high-grade materials such as ASTM A105, AISI 304/316, IS 2062, and EN1092, these flanges are highly resistant to corrosion. Surface finishes include galvanized, painted, or bare, with coating thickness tailored to specific project needs, enhancing long-term durability across varied environments.

Rigorous Testing & Certified Marking

Every flange is subject to thorough hydrostatic and dimensional inspection to guarantee conformity with international standards. Key product details including size, pressure rating, material, and standard are stamped on each flange for clear traceability and easy identification during installation and maintenance.

FAQs of Slip On Backing Flange:

Q: How is a slip on backing flange used for pipe connections?

A: A slip on backing flange is used to join pipes, especially HDPE and PVC types, by sliding over the pipe end and securing it with bolts. It provides a pressure-tight seal when paired with a compatible gasket.Q: What materials are available for these flanges and how does this benefit different applications?

A: Slip on backing flanges are manufactured from carbon steel, stainless steel, mild steel, or ductile iron. The material choice ensures compatibility with various service media, enhancing corrosion resistance and strength in water, oil, gas, or chemical pipelines.Q: Where can slip on backing flanges be installed?

A: These flanges are suitable for installation in water supply networks, gas distribution systems, industrial piping, and chemical process pipelines across both commercial and industrial settings.Q: What testing is performed to ensure product reliability?

A: Each flange undergoes hydrostatic and dimensional inspections, ensuring it meets required pressure specifications and accurate dimensions for secure and reliable performance.Q: When should you use a slip on backing flange over other types?

A: Slip on backing flanges are ideal when easy installation, alignment flexibility, and adaptability to loose pipes are priorities, especially in applications requiring standard or custom pipeline dimensions.Q: What gasket types can be used with these flanges?

A: Flanges are compatible with rubber, PTFE, or non-asbestos gaskets, allowing for effective sealing in various temperature and media conditions.Q: How does coating thickness affect flange performance?

A: Coating thickness, ranging from 35 m to 100 m, improves corrosion resistance and longevity. The specified coating is selected based on project requirements and installation environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free