PPH Stub Flange

100.0 INR/Piece

Product Details:

- Capacity 15000 Tons/year

- Port Size Available from 20mm to 315mm

- Usage Connecting pipelines, industrial liquid conveyance

- Pressure Ratings PN 10, PN 16 (varies by size)

- Diameter 20- 315 Millimeter (mm)

- Corrosion Resistant Yes

- Thread Type Not Applicable (Flanged End)

- Click to view more

X

PPH Stub Flange Price And Quantity

- 10 Piece

- 100.0 INR/Piece

- 0.91 g/cm³

- High

- Bolt-on using gasket

- Grey

- Yes

- -20°C to +80°C

- Acids, alkalis, organic solvents

- EPDM, PTFE, NBR

PPH Stub Flange Product Specifications

- Smooth, semi-gloss

- Chemical processing, water treatment, industrial piping systems

- Flanged

- Up to 16 bar

- PP-H (Polypropylene Homopolymer)

- Stub Flange

- Flanged end

- 20- 315 Millimeter (mm)

- High chemical resistance, lightweight, corrosion proof, easy to install

- Available from 20mm to 315mm

- 15000 Tons/year

- Connecting pipelines, industrial liquid conveyance

- 20- 315 Millimeter (mm)

- PN 10, PN 16 (varies by size)

- Circular with stub flange ring

- Yes

- Polypropylene Homopolymer (PPH)

- Not Applicable (Flanged End)

- 0.91 g/cm³

- High

- Bolt-on using gasket

- Grey

- Yes

- -20°C to +80°C

- Acids, alkalis, organic solvents

- EPDM, PTFE, NBR

PPH Stub Flange Trade Information

- Nhava Sheva

- Cash Advance (CA), Cash in Advance (CID), Cash Against Delivery (CAD), Cash on Delivery (COD)

- 4 Week

- Contact us for information regarding our sample policy

- Loose, Pallets or customised as per customer requirement.

- Asia

- All India

Product Description

Features:

- Compact size

- Resistant to abrasion

- Rigid design

- Non conductive

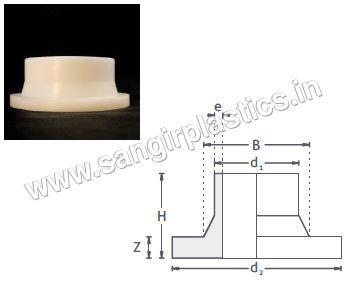

Standard Sizing:

|

Code |

d1 |

B |

d2 |

SDR7 |

SDR11 |

|

PPSE020 |

20 |

26 |

51 |

- |

7 |

|

PPSE025 |

25 |

30 |

58 |

- |

9 |

|

PPSE032 |

32 |

38 |

64 |

- |

10 |

|

PPSE040 |

40 |

44 |

70 |

- |

11 |

|

PPSE050 |

50 |

54 |

81 |

- |

12 |

|

PPSE063 |

63 |

68 |

95 |

- |

14 |

|

PPSE075 |

75 |

78 |

107 |

- |

16 |

|

PPSE090 |

90 |

96 |

126 |

- |

17 |

|

PPSE110 |

110 |

116 |

158 |

18 |

18 |

|

PPSE125 |

125 |

132 |

158 |

18 |

25 |

|

PPSE140 |

140 |

155 |

188 |

18 |

25 |

|

PPSE160 |

160 |

165 |

212 |

18 |

25 |

|

PPSE180 |

180 |

180 |

212 |

20 |

30 |

|

PPSE220 |

220 |

232 |

268 |

24 |

32 |

|

PPSE225 |

225 |

235 |

268 |

24 |

32 |

|

PPSE250 |

250 |

285 |

320 |

25 |

35 |

|

PPSE280 |

280 |

291 |

320 |

25 |

35 |

|

PPSE315 |

315 |

335 |

370 |

46 |

60 |

|

PPSE355 |

355 |

373 |

430 |

25 |

35 |

|

PPSE400 |

400 |

427 |

482 |

46 |

60 |

|

PPSE450 |

450 |

514 |

585 |

30 |

40 |

|

PPSE500 |

500 |

530 |

585 |

50 |

60 |

|

PPSE560 |

560 |

615 |

685 |

33 |

46 |

|

PPSE630 |

630 |

642 |

685 |

50 |

60 |

Weld Type: Butt

Other Information

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

Exceptional Chemical Resistance

Designed for demanding industrial environments, the PPH Stub Flange resists a wide spectrum of chemicals, including acids, alkalis, and organic solvents. This durability extends its service life, minimizes maintenance costs, and ensures reliable operation even under rigorous conditions.

Flexible Installation and Sizing

Installation is simple, utilizing bolt-on methods with compatible gaskets (EPDM, PTFE, NBR), catering to a variety of pipeline diameters from 20mm to 315mm. Standard dimensions comply with DIN & ISO specifications, making it readily compatible in new setups and retrofit projects.

Efficient Industrial Applications

The stub flange is a preferred choice in chemical processing, water treatment, and industrial liquid conveyance. Its lightweight nature and corrosion-proof properties simplify handling, increase pipeline longevity, and optimize fluid flow efficiency in critical systems.

FAQs of PPH Stub Flange:

Q: How is the PPH Stub Flange installed in a pipeline system?

A: The PPH Stub Flange is installed using a bolt-on method with a suitable gasket (such as EPDM, PTFE, or NBR), ensuring a secure and leak-proof flanged connection. It is compatible with standard flange stub ends and can be integrated into pipelines with standard DIN & ISO dimensions.Q: What types of gaskets are compatible with the PPH Stub Flange?

A: This stub flange is designed to work effectively with EPDM, PTFE, and NBR gaskets, allowing users to select the best sealing material depending on their specific chemical and temperature requirements.Q: When should the PPH Stub Flange be used in industrial piping systems?

A: The PPH Stub Flange is ideal for use when high chemical resistance, lightweight construction, and corrosion-proof performance are required. It is particularly suited for chemical processing, water treatment, and other environments handling aggressive fluids between -20 C and +80 C.Q: Where are PPH Stub Flanges typically applied?

A: PPH Stub Flanges are commonly found in chemical plants, water treatment facilities, and various industrial settings where robust, reliable pipeline connections for fluid conveyance are essential.Q: What process is involved in the installation of the PPH Stub Flange?

A: Installation involves aligning the flange ring with corresponding pipe flanges, inserting a gasket between the faces, and tightening bolts to achieve a sealed and stable connection. This process is straightforward and does not require threading, as the end type is flanged.Q: How does the PPH Stub Flange benefit industrial liquid conveyance systems?

A: Its high chemical resistance, corrosion-proof nature, and lightweight structure reduce operational downtime, maintenance, and replacement frequency, enhancing safety and reliability in liquid conveyance systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free