PVDF Lined Pipes

100.0 INR/Piece

Product Details:

- Shape Round

- Material PVDF

- Features High thermal stability, High dielectric strength

- Surface Finish Polished

- Connection Type Socket Joint

- Usage Industrial

- Click to view more

X

PVDF Lined Pipes Price And Quantity

- 1 Piece

- 100.0 INR/Piece

PVDF Lined Pipes Product Specifications

- High thermal stability, High dielectric strength

- PVDF

- Round

- Industrial

- Socket Joint

- Polished

Product Description

Owing to our rich experience of more than three decades, we are successfully affianced in manufacturing, exporting and supplying the best quality range of PVDF Lined Pipes. With the aid of contemporary techniques, our dexterous professionals use top quality polyvinylidene difluoride to manufacture these pipes. These pipes find their application in paper, sugar, pharmaceutical and food processing industries for transferring fluid one place to another. Additionally, the provided PVDF Lined Pipes can be purchased from us in various specifications at marginal prices.

Features:

Features:

- High thermal stability

- Abrasion resistance

- Fine finish

- Easy to connect

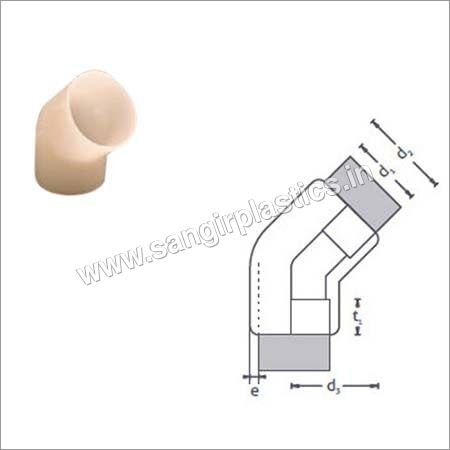

Standard Sizing:

|

Size (inches) |

d1 |

Wall thickness |

|

1 |

27.9 |

3.17 |

|

1.5 |

44.7 |

3.17 |

|

2 |

56.3 |

3.17 |

|

3 |

82.2 |

3.17 |

|

4 |

107 |

3.68 |

|

6 |

160 |

4.06 |

|

8 |

213 |

4.7 |

Features:

- High thermal stability

- High dielectric strength Readily melt processable

- Exceptional outdoor weather resistance

- Low permeability to most gases and liquids

- Low flame and smoke characteristics

- High abrasion resistance

- Very low creep

- High purity

- Resistance to most chemicals and solvents

- Resistance to nuclear radiation

- Resistance to fungi

- Very smooth surfaces can be obtained

- Mechanical strength & toughness

Applications:

- Process Industry

- Sugar Industry

- High purity applications

- Paper & pulp Industry

- Electronic, electrical & semi-conductors industry

- Nuclear power industry

- Pharmaceutical Industry

- Automotive Industry

- Solar power panels

- DI water plants

Other Details:

- Galvanized Steel, Stainless Steel Flanges available.

- PP-GF as per ASA 150 and DIN 2501 available.

Exceptional Material Strength

PVDF, or polyvinylidene fluoride, ensures these pipes remain highly resistant to chemicals, corrosion, and extreme temperatures. The materials inherent properties make them ideal for rigorous industrial applications.

Polished Finish for Enhanced Performance

A polished surface finish reduces friction and prevents buildup within the pipes, leading to more efficient fluid flow and easier maintenance. This further extends the lifespan of the pipes in demanding environments.

Reliable Socket Joint Connection

The socket joint design allows for secure and leak-proof connections, streamlining installation and reducing downtime. This connection type suits both temporary and permanent industrial piping systems.

FAQs of PVDF Lined Pipes:

Q: How are PVDF lined pipes installed in industrial applications?

A: PVDF lined pipes are typically installed using a socket joint connection, which ensures a tight, leak-proof seal. The installation process involves aligning the pipe ends and securing them with the appropriate fixtures designed for industrial systems.Q: What benefits does the high thermal stability of PVDF offer in pipe usage?

A: High thermal stability allows PVDF lined pipes to operate reliably under fluctuating and high temperatures, minimizing material deformation and ensuring consistent performance during intensive industrial processes.Q: When should PVDF lined pipes be chosen over other piping materials?

A: PVDF lined pipes are ideal when the application requires high resistance to chemicals, excellent dielectric properties, or exposure to extreme temperatures. Industries such as chemical processing, pharmaceuticals, and electronics benefit most from these features.Q: Where are PVDF lined pipes manufactured and exported from?

A: These pipes are manufactured, supplied, and exported from India, meeting international quality standards for use in global industrial markets.Q: What process is involved in the production of PVDF lined pipes?

A: PVDF lined pipes are produced by lining a base pipe with PVDF material, followed by precision polishing and quality checks. This process ensures optimal surface finish, robust durability, and superior performance characteristics.Q: How does the polished surface finish enhance PVDF lined pipe usage?

A: The polished finish minimizes internal friction, reduces the likelihood of particle buildup, and improves fluid transport efficiency. This results in easier maintenance and longer-lasting service in industrial facilities.Q: What are the primary industrial usages of PVDF lined pipes exported from India?

A: PVDF lined pipes are used primarily in chemical processing plants, pharmaceutical manufacturing, and electronic industries, where their resistance to corrosion and high dielectric strength are critical for safe and efficient operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email