PP End Caps Moulded

Product Details:

- Port Size 20mm to 160mm

- Surface Finish Smooth, Injection Moulded

- Pressure Ratings PN10, PN16

- Features Leak Proof, Durable, Chemical Resistant, Light Weight

- Material Grade PP-R High Grade

- Corrosion Resistant Yes

- Fittings End Cap

- Click to view more

PP End Caps Moulded Product Specifications

- Round

- Polypropylene (PP)

- Pressure Pipe

- High Flow Capacity

- Closed

- Socket Weld

- Customized / Standard sizes available

- 20mm to 160mm

- Water Supply, Agriculture, Chemical Transport, Industrial Pipeline

- Sealing Pipe Ends

- Up to 16 bar

- 20mm to 160mm

- Smooth, Injection Moulded

- PN10, PN16

- Leak Proof, Durable, Chemical Resistant, Light Weight

- PP-R High Grade

- End Cap

- Yes

Product Description

We are instrumental in manufacturing, exporting and supplying a wide array of PP End Caps Moulded. The offered caps are manufactured using quality tested polypropylene with innovative moulding techniques under the vigilance of our diligent professionals. Ideal to cover the one end of pipe, these caps are highly demanded among clients. In addition, the provided PP End Caps Moulded can be purchased from us in vivid specifications at marginal prices.

Features:

- Sturdy design

- Non conductive

- Accurate size

- Perfect finish

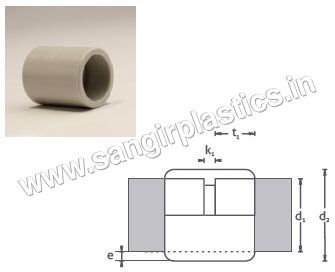

Standard Sizing:

|

Code |

Size |

d |

t1 |

e |

|

PPEC020S |

20 |

19.5 |

14.5 |

3.8 |

|

PPEC025S |

25 |

24.5 |

16 |

4.3 |

|

PPEC032S |

32 |

31.5 |

18 |

4.8 |

|

PPEC040S |

40 |

39.5 |

20.5 |

5.3 |

|

PPEC050S |

50 |

49.5 |

23.5 |

5.8 |

|

PPEC063S |

63 |

62.5 |

27.5 |

6.8 |

|

PPEC075S |

75 |

74.9 |

31 |

7.6 |

|

PPEC090S |

90 |

89.9 |

33 |

10.1 |

|

PPEC110S |

110 |

110 |

37 |

10.6 |

Weld Type: Socket

Other Information :

- Minimum Order Quantity: 10 Piece(s)

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

Leak-Proof, Durable Performance

Rely on our PP End Caps for unmatched sealing efficiency and resilience. Manufactured using advanced injection moulding, these caps feature a smooth surface finish and deliver a leak-proof, chemical-resistant solution for a range of high-flow applications. Their robust construction supports long-term operation under varying pressures.

Customizable and Easy to Install

Choose from standard or customized sizes and select your preferred color to match your system requirements. Our end caps are engineered for an easy fitno special tools are neededmaking them ideal for professional installers and DIY users alike. Each end cap securely seals pipe ends, maintaining system integrity.

Designed for Harsh Environments

With a temperature resistance of up to 80C, resistance to corrosion, and UV protection, our PP End Caps excel in demanding industrial, agricultural, and chemical environments. The high grade PP-R material ensures these caps can withstand the elements and rigorous use, providing a lifespan exceeding 20 years.

FAQs of PP End Caps Moulded:

Q: How are these PP end caps installed on pressure pipes?

A: Installation is straightforward and requires no special tools. These socket-weld end caps fit securely over the pipe end by simply pressing into position, ensuring a tight, leak-proof seal for both standard and custom pipe diameters.Q: What makes these PP end caps suitable for industrial and agricultural usage?

A: These caps are made from high-grade PP-R polypropylene, providing excellent chemical resistance, UV protection, and durability. Their ability to withstand high pressures (up to 16 bar) and temperatures (up to 80C) makes them ideal for diverse industrial, agricultural, and chemical transport applications.Q: When is it necessary to use an end cap on a pressure pipe system?

A: End caps should be used whenever the end of a pipe needs to be sealed, usually at system endpoints or during maintenance. Proper end capping prevents leaks, contamination, and system damage, ensuring the longevity of your pipeline infrastructure.Q: What customization options are available for these end caps?

A: These PP end caps can be tailored in color (black, grey, or as required) and dimensions (from 20mm to 160mm). You may select standard sizes or request custom measurements to perfectly fit your specific project or system needs.Q: Where are these end caps commonly used?

A: Our PP end caps are widely employed in water supply networks, agricultural irrigation, chemical transport pipelines, and various industrial systems due to their superior resistance to corrosion, chemicals, and environmental exposure.Q: What benefits do PP end caps offer over metal alternatives?

A: Compared to metal caps, PP end caps are lighter in weight, highly corrosion-resistant, easier to install, and provide superior chemical and UV resistance. This ensures minimal maintenance, reduced installation effort, and longer service life.Q: What is the typical process for manufacturing these end caps?

A: The end caps are manufactured through a precise injection moulding process, which produces a smooth, consistent surface finish and ensures robust structural integrity for reliable sealing and extended performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+