PVDF Pipes Fittings

100.0 INR/Piece

Product Details:

- Surface Finish Smooth / Glossy

- Pressure Ratings Up to 16 bar (varies by size and fitting)

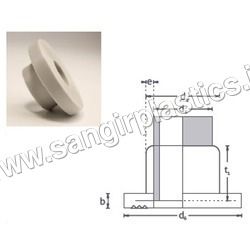

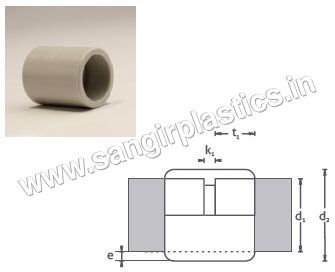

- Connection Type Socket Weld / Spigot / Threaded / Flanged

- Pipe Type Solid Extruded Pipe

- Shape Round

- Port Size Available from 20 mm to 315 mm

- Working Presssure Up to 10 bar (at 20C)

- Click to view more

X

PVDF Pipes Fittings Price And Quantity

- 1000 Piece

- 100.0 INR/Piece

- Moderate

- DIN 8077/8078, ASTM, ISO

- Excellent outdoor weathering resistance

- 1.78 g/cm³ (approx.)

- Easy solvent or heat fusion joining

- -40°C to +120°C

- Extruded and injection molded

- Typically 2.5 times working pressure

- Natural White/Semi-transparent

- Non-toxic, food-grade compliant

- Excellent insulating properties

- Self-extinguishing, UL94 V-0

PVDF Pipes Fittings Product Specifications

- High chemical resistance, UV resistant, High purity, Abrasion resistant, Lightweight

- BSPT / NPT

- Virgin PVDF (Grade: ASTM D3222, Type I/II)

- Plain, Threaded, Flanged

- Depends on pipe diameter and length

- Polyvinylidene Fluoride (PVDF)

- 20 mm to 315 mm

- Industrial piping, Acid transport, Deionized water

- Chemical processing, Water treatment, Pharmaceuticals, Food industry, Semiconductor manufacturing

- As per standard or custom requirement

- Yes

- Up to 10 bar (at 20C)

- Available from 20 mm to 315 mm

- Smooth / Glossy

- Up to 16 bar (varies by size and fitting)

- Solid Extruded Pipe

- Socket Weld / Spigot / Threaded / Flanged

- Round

- Moderate

- DIN 8077/8078, ASTM, ISO

- Excellent outdoor weathering resistance

- 1.78 g/cm³ (approx.)

- Easy solvent or heat fusion joining

- -40°C to +120°C

- Extruded and injection molded

- Typically 2.5 times working pressure

- Natural White/Semi-transparent

- Non-toxic, food-grade compliant

- Excellent insulating properties

- Self-extinguishing, UL94 V-0

Product Description

We are affianced in manufacturing, exporting and supplying PVDF Pipes Fittings to our valued clients. The offered fittings are manufactured as per industrial quality norms with the aid of pioneering techniques by our diligent professionals using supreme quality polyvinylidene difluoride. These fittings are commonly used in food processing, sugar, paper and pulp industries for leak proof connection. In addition, the provided PVDF Pipes Fittings can be purchased from us at cost effective prices.

Features:

- Compact size

- High durability

- Simple to fit

- Sturdiness

Applications:

- Process Industry

- Sugar Industry

- High purity applications

- Paper & pulp Industry

- Electronic, electrical & semi-conductors industry

- Nuclear power industry

- Pharmaceutical Industry

- Automotive Industry

- Solar power panels

- DI water plants

Other Information

- Minimum Order Quantity: 10 metres

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

Superior Chemical and UV Resistance

PVDF pipe fittings excel in environments exposed to strong chemicals and UV radiation. Their high purity and resistant nature safeguard piping against aggressive acids, solvents, and outdoor conditions, making them ideal for industries like chemical processing and water treatment. The smooth, glossy surface finish further reduces risks of contamination and supports cleanroom applications.

Flexible Installation and Reliable Connections

Designed for easy installation, PVDF fittings accommodate several joining methods including solvent welding, heat fusion, socket weld, spigot, threaded, and flanged connections. These options enable hassle-free assembly tailored to site requirements, ensuring secure, leak-resistant systems in both standard and custom dimensions.

Food Grade and Flame Retardant Certified

All PVDF fittings are non-toxic and compliant with food-grade standards, supporting their use in sensitive sectors such as pharmaceuticals and food manufacturing. They feature self-extinguishing flame retardancy (UL94 V-0), enhancing safety during operation and minimizing risk in the event of fire.

FAQs of PVDF Pipes Fittings:

Q: How can PVDF pipe fittings be installed in industrial systems?

A: PVDF pipe fittings can be installed using a range of connection methods such as solvent welding, heat fusion, socket weld, spigot, threaded, or flanged joints, which allow for fast and reliable assembly according to project requirements.Q: What advantages do PVDF pipe fittings offer for chemical processing applications?

A: PVDF pipe fittings provide exceptional chemical resistance, high purity, UV stability, and corrosion protection, making them suitable for transporting aggressive acids, deionized water, and chemicals in industrial environments.Q: Where are PVDF pipe fittings commonly used?

A: These fittings are frequently utilized in sectors like chemical processing, water treatment, pharmaceutical manufacturing, food industries, and semiconductor production due to their non-toxic nature and robust performance.Q: When is it beneficial to choose PVDF over other piping materials?

A: PVDF is advisable when high chemical resistance, food-grade compliance, and flame retardancy are required, particularly in environments exposed to corrosive substances or extreme temperatures ranging from -40C to +120C.Q: What is the process for joining PVDF pipe fittings?

A: Joining is straightforward and can be performed with solvent or heat fusion methods. Both techniques create strong, leak-proof bonds, suited for industrial piping where reliability is crucial.Q: Are PVDF pipe fittings safe for use in applications involving food or drinking water?

A: Yes, PVDF pipe fittings are non-toxic and compliant with food-grade regulations, making them safe for potable water and food-related applications.Q: What benefits do PVDF fittings provide regarding outdoor installations?

A: PVDF features outstanding UV stability and is self-extinguishing, which ensures reliable performance and safety, even during prolonged exposure to sunlight and outdoor environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email