HDPE Pipe Fittings

100.0 INR/Meter

Product Details:

- Fittings Elbows, Reducers, Couplings, Tees, Valves, Flanges, Caps Nipples

- Diameter 6 Millimeter (mm)

- Surface Finish Hot Rolled

- Usage Plumbing & Structure Pipe

- Dimension (L*W*H) 20-1200 Millimeter (mm)

- Application Water, Waste-Water, Effluents, Gas, Slurry, Dredging, etc

- Click to view more

X

HDPE Pipe Fittings Price And Quantity

- 100.0 INR/Meter

- 100 Meter

HDPE Pipe Fittings Product Specifications

- Hot Rolled

- Yes

- Plumbing & Structure Pipe

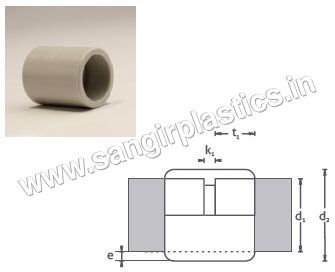

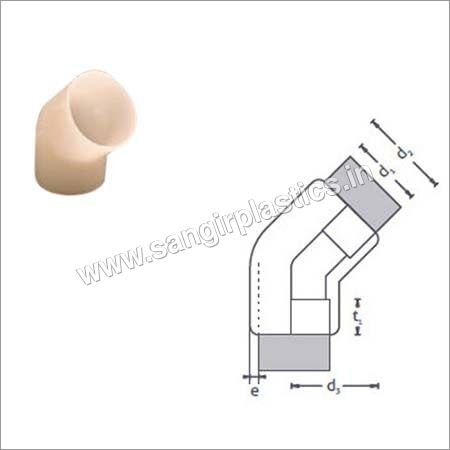

- Elbows, Reducers, Couplings, Tees, Valves, Flanges, Caps Nipples

- 6 Millimeter (mm)

- Water, Waste-Water, Effluents, Gas, Slurry, Dredging, etc

- PE 100

- HDPE

- 20-1200 Millimeter (mm)

- Round

HDPE Pipe Fittings Trade Information

- IS 4985:1995 PE 100 Grade IS 4984 PE 100 and IS 14333 PE 100 Grade HDPE & MDPE Pipe fittings as per ISO 4427 PE63, PE80 & PE100 grades.

Product Description

HDPE Pipe Fittings are manufactured under the observation of our skilled professionals with the aid of progressive techniques using quality approved high density polyethylene. Moreover, we are offering these HDPE Pipe Fittings in numerous specifications at marginal prices.

Features:

- Accurate size

- Easy to fit

- Fine finish

- High durability

HDPE Pipe Fittings are offered by Sangir. These HDPE Pipe fittings are available in the following standards:

- IS 4985:1995 PE 100 Grade

- IS 4984 PE 100 and IS 14333 PE 100 Grade

- HDPE & MDPE Pipe fittings as per ISO 4427 PE63, PE80 & PE100 grades.

HDPE Pipe Fittings can be welded by any of the following ways:

- Butt Weld

- Socket Weld

- Electro fusion Weld

- Flange Connections

- Extrusion Welding

HDPE Pipe Fittings offered by Sangir are available in the following types:

- Moulded Bends 90 Deg

- Moulded Tee 90 Deg

- Stubend/ Adaptor - short neck

- Stubend/ Adaptor - Long neck

- Moulded end Cap

- Moulded Concentric Reducer

- Butterfly valve spacer

- Fabricated Segment Bend 90 Deg

- Fabricated Segment Bend 30 Deg, 45 Deg, 60 Deg

- Backing Flanges- With and Without Steel Inserts

Excellent Chemical and Corrosion Resistance

The combination of high-grade materials like HDPE, PP, PVC, and PVDF provides outstanding resistance to corrosion and chemical reactions. This makes these pipe fittings ideal for use in harsh water and chemical environments, ensuring longevity and minimal maintenance requirements over time.

Precision Engineering for Diverse Applications

HDPE pipe fittings feature a round shape with a hot-rolled surface finish, delivering structural integrity for both plumbing and construction needs. With diameters starting at 6 mm, these fittings are suitable for systems of various sizes, offering flexible solutions for manufacturers, suppliers, and exporters.

FAQs of HDPE Pipe Fittings:

Q: How are HDPE pipe fittings installed in plumbing and structural systems?

A: HDPE pipe fittings are typically joined using methods like butt fusion, electrofusion, or mechanical couplings. Their round shape and smooth, hot-rolled surface ensure easy alignment and secure fitting during installation, enabling reliable connections in both plumbing and structural applications.Q: What materials are used in the manufacturing of these pipe fittings?

A: These fittings are manufactured using a range of durable polymers including PP, PPH, HDPE, PE100, PE80, LDPE, PVDF, PVC, and CPVC. Each material offers specific benefits in terms of strength, chemical resistance, and flexibility, catering to various industrial and commercial requirements.Q: When should HDPE pipe fittings be preferred over metal alternatives?

A: HDPE pipe fittings are recommended when corrosion resistance, lightweight handling, and flexibility are required. They are ideal for installations in environments exposed to chemicals or moisture, where metal fittings may corrode or degrade more quickly.Q: Where are these HDPE pipe fittings exported and supplied from?

A: These pipe fittings are manufactured and exported from India, ensuring global availability for diverse projects. Leading suppliers and manufacturers in India offer these fittings to international clients, guaranteeing quality and timely delivery.Q: What is the benefit of a hot-rolled surface finish for these pipe fittings?

A: The hot-rolled surface finish enhances the strength and durability of the fittings while providing a smooth exterior for leak-proof connections. This finish also simplifies installation and minimizes wear during handling and use.Q: What is the main usage of these HDPE pipe fittings?

A: They are primarily used in plumbing and structural piping systems, offering reliable and corrosion-resistant solutions for water supply, chemical transport, and industrial applications.Q: What process is followed to ensure the corrosion resistance of these fittings?

A: Corrosion resistance is achieved by selecting polymers inherently resistant to chemicals and moisture. The manufacturing process incorporates strict quality control and advanced engineering techniques to maintain high performance and durability under demanding conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email