PVDF Pipe- ASTM Standard

Product Details:

- Working Presssure 6-16 bar (dependent on diameter and temperature)

- Connection Type Socket Weld

- Fittings Socket, Union, Elbow, Tee, Reducer, Flange

- Corrosion Resistant Yes

- Diameter 20 mm to 160 mm

- Usage Liquid and Gas Transmission

- Thread Type Not Applicable (Socket Weld)

- Click to view more

PVDF Pipe- ASTM Standard Price And Quantity

- 100 INR

- 1000

PVDF Pipe- ASTM Standard Product Specifications

- Socket Weld

- 6-16 bar (dependent on diameter and temperature)

- Yes

- 20 mm to 160 mm

- Socket, Union, Elbow, Tee, Reducer, Flange

- Not Applicable (Socket Weld)

- Liquid and Gas Transmission

- Round Pipe

- ASTM D3222 Type I and II

- 1/2 inch to 6 inch

- Up to 16 bar

- Polyvinylidene Fluoride (PVDF)

- Round

- High purity, UV resistant, Lightweight, High chemical resistance

- Chemical Processing, Water Treatment, Food & Beverage Industry, Pharmaceutical

- Smooth, Glossy

- Varies by size

- Plain / Socket

- Custom sizes available

Product Description

Due to our up-to-date production unit, we are able to manufacture, export and supply the best-in-quality PVDF Pipe- ASTM Standard. This pipe is manufactured under the proper supervision of our ingenious professionals using high grade polyvinylidene difluoride with the aid of modern techniques. The offered pipe find its application in food processing, chemical, fertilizer, paint, petroleum and pharmaceutical industries for leak proof passage of fluid. In addition, the provided PVDF Pipe- ASTM Standard can be purchased from us in various specifications at industry leading prices.

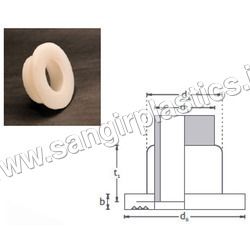

Standard sizing:

| Sch 40 | Sch 80 | |||||

| Size (inches) | d1 (inches) | d1 (mm) | e (inches) | mm | e (inches) | mm |

| 0.5 | 0.84 | 21.34 | 0.109 | 2.77 | 0.147 | 3.73 |

| 0.75 | 1.05 | 26.67 | 0.113 | 2.87 | 0.154 | 3.91 |

| 1 | 1.315 | 33.4 | 0.133 | 3.38 | 0.179 | 4.55 |

| 1.25 | 1.66 | 42.16 | 0.14 | 3.56 | 0.191 | 4.85 |

| 1.5 | 1.9 | 48.26 | 0.145 | 3.68 | 0.2 | 5.08 |

| 2 | 2.375 | 60.33 | 0.154 | 3.91 | 0.218 | 5.54 |

| 2.5 | 2.875 | 73.03 | 0.203 | 5.16 | 0.276 | 7 |

| 3 | 3.5 | 88.9 | 0.216 | 5.49 | 0.3 | 7.62 |

Features:

- Mechanical strength & toughness

- High thermal stability

- High dielectric strength

- Readily melt processable

- Exceptional outdoor weather resistance

- Low permeability to most gases and liquids

- Low flame

- High abrasion resistance

- Very low creep

- High purity

- Resistance to most chemicals and solvents

- Resistance to nuclear radiation

- Resistance to fungi

- Very smooth surfaces can be obtained

Applications:

- Process Industry

- Sugar Industry

- High purity applications

- Paper & pulp Industry

- Electronic, electrical & semi-conductors industry

- Nuclear power industry

- Pharmaceutical Industry

- Automotive Industry

- Solar power panels

- DI water plants

- Minimum Order Quantity: 10 Meter(s)

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, pallets or customized as per customers requirement.

Unmatched Chemical & UV Resistance

PVDF pipes comply with ASTM D3222 standards, boasting high resistance to a wide range of corrosive chemicals and prolonged UV exposure. This makes them exceptionally suitable for outdoor or highly corrosive industrial environments, ensuring reliability and extended service life.

Versatile Applications and Custom Sizing

These pipes are engineered for use in numerous sectors such as chemical processing, water treatment, pharmaceutical, and food & beverage industries. With custom sizing options (from 20 mm to 160 mm diameter) and a range of compatible fittings, they cater to varied installation needs.

Efficient Installation & Low Maintenance

Featuring smooth, glossy surfaces and lightweight construction, PVDF pipes are easy to install and require minimal upkeep. Socket weld connections allow for secure, leak-free joints, supporting efficient workflows and reducing maintenance downtime.

FAQs of PVDF Pipe- ASTM Standard:

Q: How does PVDF piping perform in extreme temperatures?

A: PVDF pipes are designed to function reliably within a broad temperature range of -40C to +140C, making them suitable for both cryogenic and high-temperature industrial processes without compromising mechanical integrity.Q: What benefits does PVDF pipe offer over traditional piping materials?

A: PVDF pipes provide superior chemical and UV resistance, outstanding tensile strength, self-extinguishing flame retardancy, and a long service life. These qualities make them ideal for demanding environments where other materials may degrade quickly.Q: Where are PVDF pipes typically installed?

A: PVDF piping is commonly used in chemical processing plants, water treatment facilities, the food and beverage sector, and pharmaceutical industries due to its high purity and resistance to corrosion, making it suitable for both liquid and gas transmission.Q: What is the installation process for PVDF pipes and fittings?

A: Installation is straightforward thanks to the socket weld connection system. Pipes and compatible fittingssuch as elbows, tees, unions, reducers, and flangesare easily joined, ensuring a secure and leak-proof setup.Q: When should PVDF pipes be chosen for a project?

A: Choose PVDF piping when your project demands high-level chemical resistance, exposure to UV light, superior mechanical properties, and where extended service life and low maintenance are critical, particularly in corrosive or aggressive environments.Q: What are the available sizes and pressure ratings for these pipes?

A: PVDF pipes are offered in diameters from 20 mm to 160 mm and support working pressures between 6 and 16 bar, depending on the pipe diameter and operating temperature. Custom sizes are also available to fit unique application needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free