HDPE Molded Stub End

Product Details:

- Corrosion Resistant Yes

- Usage Pipe Connection/Dismantling

- End Type Stub (Flanged) End

- Capacity 15000 Tons/year

- Surface Finish Smooth

- Pipe Type Stub End

- Diameter 20-1200 Millimeter (mm)

- Click to view more

HDPE Molded Stub End Price And Quantity

- 1 Kilograms

- 100.0 INR/Kilograms

HDPE Molded Stub End Product Specifications

- Lightweight, Durable, Leak Proof, UV Resistant

- HDPE (High Density Polyethylene)

- PN6, PN8, PN10, PN12.5, PN16

- 20mm to 630mm

- PE100, PE80

- Up to 16 bar

- Stub End (Short Neck/Long Neck as required)

- Water supply, Industrial piping, Plumbing

- Butt Weld

- Not applicable (Butt Weld Fitting)

- Smooth

- Stub (Flanged) End

- Pipe Connection/Dismantling

- Yes

- 15000 Tons/year

- 52-170 Millimeter (mm)

- Stub End

- 20-1200 Millimeter (mm)

Product Description

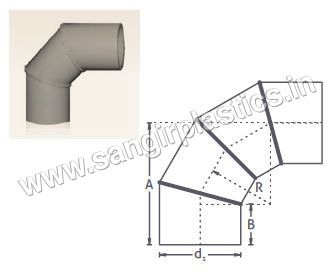

HDPE Molded Stub End, Adapter- Short Neck

Standard sizing:

|

Code |

d1 |

B |

D2 |

L |

SDR17 |

SDR11 |

SDR9 |

SDR7.4 |

|

(A) |

(A |

(A |

(A |

|||||

|

PESE020 |

20 |

27 |

45 |

52 |

7 |

7 |

7 |

7 |

|

PESE025 |

25 |

33 |

58 |

53 |

9 |

9 |

9 |

9 |

|

PESE032 |

32 |

40 |

68 |

52 |

10 |

10 |

10 |

10 |

|

PESE040 |

40 |

50 |

78 |

51 |

11 |

11 |

11 |

11 |

|

PESE050 |

50 |

61 |

88 |

53 |

12 |

12 |

12 |

12 |

|

PESE063 |

63 |

75 |

95 |

50 |

14 |

15 |

17 |

19 |

|

PESE075 |

75 |

88 |

108 |

50 |

16 |

17 |

18 |

21 |

|

PESE090 |

90 |

103 |

129 |

80 |

17 |

18 |

20 |

22 |

|

PESE110 |

110 |

124 |

158 |

80 |

18 |

19 |

22 |

23 |

|

PESE125 |

125 |

128 |

158 |

80 |

18 |

25 |

28 |

31 |

|

PESE140 |

140 |

151 |

187 |

80 |

18 |

25 |

29 |

31 |

|

PESE160 |

160 |

168 |

213 |

80 |

18 |

26 |

29 |

32 |

|

PESE180 |

180 |

190 |

213 |

80 |

20 |

30 |

34 |

36 |

|

PESE200 |

200 |

225 |

270 |

95 |

24 |

32 |

36 |

39 |

|

PESE225 |

225 |

230 |

270 |

95 |

24 |

32 |

36 |

39 |

|

PESE250 |

250 |

284 |

322 |

100 |

25 |

35 |

38 |

42 |

|

PESE280 |

280 |

294 |

334 |

100 |

25 |

35 |

38 |

42 |

|

PESE315 |

315 |

335 |

380 |

100 |

25 |

35 |

38 |

42 |

|

PESE355 |

355 |

366 |

442 |

110 |

30 |

40 |

45 |

50 |

|

PESE400 |

400 |

420 |

495 |

110 |

33 |

45 |

50 |

55 |

|

PESE450 |

450 |

470 |

545 |

110 |

46 |

45 |

50 |

55 |

|

PESE500 |

500 |

520 |

596 |

125 |

46 |

60 |

65 |

72 |

|

PESE560 |

560 |

580 |

657 |

125 |

50 |

60 |

65 |

72 |

|

PESE630 |

630 |

650 |

710 |

130 |

50 |

60 |

65 |

72 |

|

PESE710 |

710 |

735 |

800 |

130 |

50 |

60 |

65 |

72 |

|

PESE800 |

800 |

825 |

940 |

130 |

50 |

60 |

65 |

72 |

|

PESE900 |

900 |

940 |

1050 |

130 |

50 |

60 |

65 |

72 |

|

PESE1000 |

1000 |

1025 |

1125 |

130 |

60 |

60 |

65 |

72 |

|

PESE1200 |

1200 |

1230 |

1330 |

170 |

70 |

80 |

90 |

100 |

Type: Butt Weld

- Minimum Order Quantity: 1Kilogram(s)

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 10000 metric tons per year

- Delivery Time: 3-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

Engineered for Performance and Longevity

This HDPE Molded Stub End stands out for its high pressure handling, supported by a durable design and advanced molding technique. Its compliance with major international standards ensures reliability for both water supply and industrial applications. PE100 or PE80 grades combined with UV stabilization make it ideal for extended outdoor service.

Easy Installation and Versatile Compatibility

Designed for butt weld connections, the stub end seamlessly fits HDPE pipe flange adapters and backing rings. Molded with a smooth surface and lightweight material, it streamlines the installation process. The product is corrosion-resistant and leak-proof, offering a secure solution in various operational environments.

FAQs of HDPE Molded Stub End:

Q: How is the HDPE Molded Stub End installed in a pipeline system?

A: The HDPE Molded Stub End is installed using a butt weld technique. This involves aligning the stub end with the pipe and using fusion welding equipment to create a strong, seamless joint. It is then paired with a backing ring and flange adapter for secure connection and easy dismantling.Q: What are the main benefits of using a molded HDPE stub end for pipe connections?

A: Using a molded HDPE stub end offers several benefitsits lightweight yet durable, resistant to corrosion and UV rays, and provides a leak-proof connection. Its smooth surface and high tensile strength make it ideal for high-pressure applications, and it ensures reliable performance with a service life of up to 50 years.Q: In what environments is this product best used, considering its properties?

A: This molded stub end is suited for outdoor and indoor environments, including water supply networks, industrial piping, and plumbing systems. Thanks to its UV stabilization, corrosion resistance, and compliance with IS 4984, ISO 4427, and DIN 8074 standards, it performs excellently in both harsh and standard conditions.Q: What pressure ratings and sizes are available for the HDPE Molded Stub End?

A: This stub end can handle working pressures up to 16 bar, with available pressure ratings of PN6, PN8, PN10, PN12.5, and PN16. It is manufactured in a diameter range from 20mm to 630mm OD, ensuring suitability for a wide spectrum of project requirements.Q: Why is injection molding used in the manufacturing process of this stub end?

A: Injection molding is chosen for manufacturing due to its ability to produce components with precise dimensions, smooth surface finishes, and consistent material strength. This process enhances the fittings durability, leak proofing, and reliability in various applications.Q: What material grades are available for the HDPE molded stub end, and how do they benefit users?

A: The stub end is offered in PE100 and PE80 grades, which provide high mechanical strength and long-term durability. These material grades ensure resistance against environmental stress, high pressure, and impact, making the fitting suitable for critical water and industrial piping systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+