HDPE Dredge Pipes

Product Details:

- Dimension (L*W*H) Varies (customized as per requirement)

- Diameter 110 mm to 1000 mm

- Thread Type Non-threaded (Flange/Joints Only)

- Corrosion Resistant Yes

- Shape Round/Cylindrical

- End Type Flanged / Plain End / Butt Weld

- Features Flexible, Lightweight, UV Resistant, Durable, Impact Resistant

- Click to view more

HDPE Dredge Pipes Price And Quantity

- 1000 Piece

- 100.0 INR/Piece

- Low, due to material resistance properties

- From 6 mm to 60 mm (as per diameter and pressure rating)

- Standard 6m/12m; customizable

- Easy to handle and install, low manpower requirement

- Abrasion, Chemical, UV, and Impact Resistant

- Black (standard), with yellow stripes or customized

- -40°C to +80°C

- Optional internal/external liners available

- Over 50 years (normal conditions)

- Excellent flexibility for marine and river use

- Can be equipped with floaters for surface installations

- Varies by diameter and length; lightweight compared to steel

HDPE Dredge Pipes Product Specifications

- 2 to 16 bar (standard)

- Up to PN16 (16 bar)

- Dredging, slurry transport, sand & mud conveying

- PE100 / PE80

- Marine dredging, River and Lake rehabilitation, Mining slurry conveyance

- Smooth/Polished

- High flow capacity, customized to project

- HDPE (High Density Polyethylene)

- Dredge Pipe

- Flexible, Lightweight, UV Resistant, Durable, Impact Resistant

- Flanged / Plain End / Butt Weld

- Available from 110 mm to 1000 mm

- Varies (customized as per requirement)

- 110 mm to 1000 mm

- Non-threaded (Flange/Joints Only)

- Yes

- Round/Cylindrical

- Flange Joint / Welded Ends

- Low, due to material resistance properties

- From 6 mm to 60 mm (as per diameter and pressure rating)

- Standard 6m/12m; customizable

- Easy to handle and install, low manpower requirement

- Abrasion, Chemical, UV, and Impact Resistant

- Black (standard), with yellow stripes or customized

- -40°C to +80°C

- Optional internal/external liners available

- Over 50 years (normal conditions)

- Excellent flexibility for marine and river use

- Can be equipped with floaters for surface installations

- Varies by diameter and length; lightweight compared to steel

Product Description

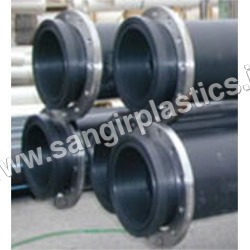

Known for 34 years of industrial experience in this domain, we are engaged in manufacturing, exporting and supplying HDPE Dredge Pipes. These pipes are manufactured using quality approved high density polyethylene with the aid of advanced techniques under the vigilance of ingenious professionals. The offered pipes find their extensive usage in marine sector for leak free transportation of fluid. Additionally, our valued clients can purchase these HDPE Dredge Pipes in numerous specifications at competitive prices.

Features:

- Resistant to abrasion

- High strength

- Accurate diameters

- Flexible for rough sea condition

Dredge Pipeline Floats are available in standards ISO 4427 and IS 4984:1995.

Standard Sizing:

|

Per ISO 4427 |

Grade PE 100 |

Sizes in mm |

||

|

OD(mm) |

Inches |

ID, PN 6 |

ID, PN 8 |

ID, PN 10 |

|

|

|

SDR 26 |

SDR 21 |

SDR 17 |

|

200 |

8" |

184 |

180 |

175 |

|

225 |

8" |

207 |

202 |

197 |

|

250 |

10" |

230 |

225 |

219 |

|

280 |

10" |

257 |

252 |

245 |

|

315 |

12" |

289 |

283 |

276 |

|

355 |

14" |

326 |

319 |

310 |

|

400 |

16" |

368 |

360 |

350 |

|

450 |

18" |

414 |

405 |

394 |

|

500 |

20" |

460 |

450 |

437 |

|

560 |

22" |

515 |

504 |

490 |

|

630 |

24" |

579 |

567 |

551 |

|

Per IS 4984:95 |

Grade PE 100 |

Sizes in mm |

||

|

OD(mm) |

Inches |

ID, PN 6 |

ID,PN 8 |

ID, PN 10 |

|

|

|

SDR 21 |

SDR 17 |

SDR 13.6 |

|

200 |

8" |

181 |

175 |

169 |

|

225 |

8" |

203 |

196 |

190 |

|

250 |

10" |

226 |

218 |

211 |

|

280 |

10" |

253 |

245 |

237 |

|

315 |

12" |

285 |

275 |

266 |

|

355 |

14" |

321 |

310 |

300 |

|

400 |

16" |

361 |

348 |

336 |

|

450 |

18" |

406 |

392 |

379 |

Features:

- Made from advanced grade of PE material.

- Light Weight - Easy installation

- Superb Flexibility for rough sea conditions

- Excellent Weathering & UV resistance

- High resistance to abrasion and corrosion.

- Stubends and flanges also installed at both ends.

- Gaskets and galvanised nuts are also provided to enable easy installation.

- Pipes are produced as per ISO 4427 - PE100 grade and IS 4984 - PE 63/ 80/ 100 grades standards.

- Structure is homogeneous throughout.

- Variety of fittings available as per requirement.

- Pressure rating of PN 6 - PN 16

- Color options are also available to customers.

Applications:

- Dredge Pipe Lines

- Water Transportation

- Slurry Transportation

- Floating Cable Casing Lines

- Aquaculture breeding area cages

- Ocean Filth blockers

- Swimming pool markers

Other Information

- Port of Dispatch: Nhava Sheva Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customised as per customer requirement.

FAQs of HDPE Dredge Pipes:

Q: How are HDPE dredge pipes installed and what makes the installation process easy?

A: HDPE dredge pipes are lightweight and flexible, which drastically reduces the manpower and equipment needed for installation. They can be installed with either flanged joints or welded ends, depending on project requirements. The pipes can be delivered in standard lengths (6m/12m) or tailored to suit, making them convenient for handling on-site. Their simple connection design expedites setup, whether for temporary or permanent applications.Q: What are the main benefits of using HDPE dredge pipes compared to traditional steel pipes?

A: HDPE dredge pipes offer several advantages over steel pipes: they are significantly lighter, making transport and installation easier and faster. Their exceptional resistance to abrasion, chemicals, UV radiation, and impact translates to an extended service life and minimal maintenance. Unlike steel, they are corrosion resistant, suitable for harsh marine and industrial environments.Q: When should I use internal or external liners for HDPE dredge pipes?

A: Internal or external liners are recommended when transporting highly abrasive or chemically aggressive materials. Liners provide an extra layer of protection, extending the pipes service life. Specify the need for liners when discussing your application with the manufacturer or supplier to ensure the optimal configuration for your project.Q: Where are HDPE dredge pipes typically used?

A: HDPE dredge pipes are commonly used in marine dredging, river and lake rehabilitation, mining slurry transport, and sand or mud conveying applications. They are ideal for environments where flexibility, high flow capacity, and resistance to environmental stress are critical.Q: What customization options are available for HDPE dredge pipes?

A: You can customize HDPE dredge pipes with a variety of lengths, diameters (110 mm to 1000 mm), wall thicknesses (6 mm to 60 mm), pressure ratings (up to PN16), colors (standard black with yellow stripes or as requested), flanged or butt-welded ends, and optional linings or floaters for surface installations. Customized fittings like steel or HDPE flanges are also available.Q: How do the temperature and pressure ratings of HDPE dredge pipes impact their usage?

A: HDPE dredge pipes function reliably in temperatures ranging from -40C to +80C, making them suitable for diverse climates. With working pressures from 2 to 16 bar and pressure ratings up to PN16, they handle both low and high-pressure applications common in dredging and slurry transport. Users should select the appropriate wall thickness and grade to match their projects demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+