PVDF Stub End

Product Details:

- Diameter Available from 1/2 to 12

- Pressure Ratings Up to 16 Bar (Depending on Size and Standard)

- Corrosion Resistant Yes

- Port Size DN15 to DN300 / 1/2 to 12

- Thread Type Not Applicable (Stub End Flanged End)

- Pipe Type Stub End

- Application Chemical Processing, Water Treatment, Industrial Piping Systems

- Click to view more

X

PVDF Stub End Product Specifications

- Polyvinylidene Fluoride (PVDF)

- Industrial, Pharmaceutical, Water Treatment, Chemical Processing

- Pipe Fitting

- 6-16 Bar (Varies by Dimension)

- Socket Weld / Butt Weld

- As per standard sizes / Customization available

- Virgin PVDF / ASTM D3222

- Standard / Custom as per Requirement

- Not Applicable (Stub End Flanged End)

- Stub End

- Chemical Processing, Water Treatment, Industrial Piping Systems

- Excellent Chemical Resistance, High Thermal Stability, Non-Toxic, UV Resistant

- Stub (short/long)

- Smooth / Polished

- Flanged / Buttweld / Socket Weld

- Available from 1/2 to 12

- Up to 16 Bar (Depending on Size and Standard)

- DN15 to DN300 / 1/2 to 12

- Yes

Product Description

In place of welded flanges, PVDF Stub End is offered. This long stubend has amazing qualities such being robust, resilient, and corrosion resistant. This is used to join pipes of various sizes and has a variety of uses in the chemical, construction, paper, cement, and shipbuilding industries. Our PVDF Stub End has been thoroughly tested for durability, precision, and accuracy. Our product is extremely cost-effective, and it is readily available in big quantities at low prices. This is safe to use.

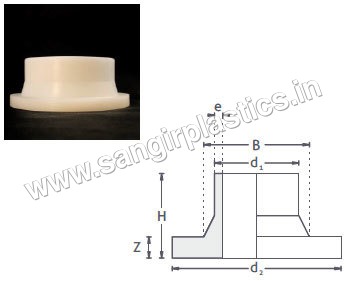

Standard sizing:

|

D |

H |

E |

D2 |

Z |

|

20 |

35 |

3 |

45 |

6 |

|

25 |

35 |

3 |

60 |

6 |

|

32 |

50 |

4 |

65 |

6 |

|

40 |

50 |

4 |

72 |

6 |

|

50 |

50 |

5 |

81 |

8 |

|

63 |

50 |

5 |

95 |

8 |

|

75 |

50 |

6 |

104 |

10 |

|

90 |

72 |

6 |

126 |

10 |

|

110 |

72 |

6 |

158 |

10 |

|

140 |

78 |

8 |

195 |

12 |

|

160 |

78 |

10 |

216 |

12 |

Features:

- Chemical & corrosion resistance

- Low maintenance

- Low electrical and thermal conductivity

- Easy installation

Other Information:

- Minimum Order Quantity: 10 Piece(s)

- Port of Dispatch: Nhava Sheva, Mumbai

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customized as per customer requirement.

Superior Chemical and Thermal Resistance

PVDF Stub Ends excel in environments requiring protection against harsh chemicals and elevated temperatures, with a reliable operating range from -40C to +140C. Their robust construction and virgin PVDF material ensure durability and longevity, minimizing maintenance and replacement needs in chemical processing, water treatment, and industrial piping systems.

Easy Installation and Flange Compatibility

Installation is straightforward thanks to the design that suits both socket weld and butt weld connections. PVDF Stub Ends are compatible with PP, PVC, and PVDF flanges, making integration with existing piping systems effortless. The products are leak-proof when properly installed and can be customized to fit any project specification.

FAQs of PVDF Stub End:

Q: How are PVDF Stub Ends installed in piping systems?

A: PVDF Stub Ends are installed using socket weld or butt weld techniques and require a matching flange for secure attachment. Installation is straightforward, and correct positioning ensures leak-proof joints.Q: What applications are PVDF Stub Ends suitable for?

A: These fittings are ideal for chemical processing, water treatment, industrial, and pharmaceutical piping systems due to their excellent chemical resistance, thermal stability, and food-grade certification.Q: What temperature range can a PVDF Stub End withstand during operation?

A: PVDF Stub Ends are designed to operate efficiently within a temperature range of -40C to +140C, making them suitable for processes involving both cold and hot media.Q: Where can PVDF Stub Ends be used for maximum benefit?

A: For maximum benefit, PVDF Stub Ends should be used in environments where superior chemical resistance, UV durability, hygienic standards, and pressure integrity are essentialsuch as in chemical plants, water purification setups, and pharmaceutical manufacturing.Q: What is the manufacturing process for PVDF Stub Ends and why is it beneficial?

A: PVDF Stub Ends are manufactured through precise injection moulding or machining, resulting in a smooth, polished finish and accurate dimensions. This ensures optimal fit, aesthetics, and performance.Q: Are PVDF Stub Ends compatible with different flange materials?

A: Yes, PVDF Stub Ends are compatible with PP, PVC, and PVDF flanges, providing flexibility in system design and material selection.Q: What makes PVDF Stub Ends advantageous over other pipe fittings?

A: Their excellent chemical and UV resistance, food-grade certification, non-toxicity, and high pressure ratings up to 16 Bar give PVDF Stub Ends a significant advantage in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free