PVC Sheets

100.0 INR/Piece

Product Details:

- Material Plastic, PVC

- Application Industrial

- Corrosion Resistant Yes

- Shape Sheet

- Diameter 1.2-10 Millimeter (mm)

- Usage Nuclear Power Plant, ,Electricity Boards, Refineries (DM Water Plants) , Chemical Industries, Power Plant, Defence (Ordinance Factories ) , Cement Industries , Textile Industries, Paper Industries

- Surface Finish Smooth Internal Surface

- Click to view more

X

PVC Sheets Price And Quantity

- 100.0 INR/Piece

- 100 Piece

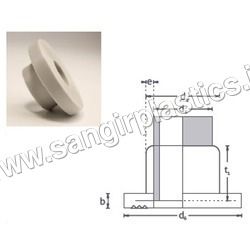

PVC Sheets Product Specifications

- Yes

- Nuclear Power Plant, ,Electricity Boards, Refineries (DM Water Plants) , Chemical Industries, Power Plant, Defence (Ordinance Factories ) , Cement Industries , Textile Industries, Paper Industries

- Industrial

- Plastic, PVC

- Sheet

- Smooth Internal Surface

- Excellent Chemical Resistance

- 1.2-10 Millimeter (mm)

- Premium

- 15000 Tons/year

PVC Sheets Trade Information

- Nhava Sheva

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- 15000 Piece Per Year

- 4 Week

- Within a certain price range free samples are available

- Pallets/ Loose/ Customised. Packaging shall ensure smooth and safe transport of materials whether dispatched inland or overseas

- All India

- ISO 1183, ISO 527, ISO 179, ISO 178, DIN 53752, VDE 0303

Product Description

As an ISO 9001:2008 certified enterprise, we manufacture, export and supply the top quality range of PVC Sheets. The provided sheets are manufactured under the strict guidance of our dexterous professionals using quality approved polyvinyl chloride and contemporary techniques by keeping in industrial quality norms. These sheets are extensively used for manufacturing chemical vessel, duct, vessel lining, chemical flooring, valve housing and equipment. Besides, the offered Rigid PVC Sheets can be purchased from us in numerous specifications at reasonable prices.

- Strong & durable

- Good Dimensional Strength

- Good Electrical insulation

- Fire Retardant Properties

- Good Chemical Resistance

- Low Moisture Absorption

- Easy to join using Solvent Cement

- Easy to weld like other thermoplastics

- Wide skill / experience availability for fabrication activities

- FDA compliant

Applications:

- Chemical tanks and vessels

- Ducts and gutters to carry chemicals

- Control cabinets and panels

- Equipment for corrosive environments

- Paper making chemicals

- Vessel Lining

- Chemical Flooring

- Flexible PVC Strip Curtains

- Industrial Fabrication activity

- Valve and Pump Housing

- Manifolds & Slurry Conveyance

- Fire retardant applications

- Fume Scrubbers & FRP Applications

Colors:

- Gray

- Dark gray

Specifications:

| Thickness | Width x Length | Packing |

| (mm) | (m) | |

| 0.2 - 1 | 0 | 10 pcs |

| 2 | 1.22 x 2.44 | |

| 3 | 1.25 x 2 | |

| 4 | ||

| 5 | ||

| 6 | ||

| 8 | ||

| 10 | 1 x 2 | |

| 12 | ||

| 15 | ||

| 20 | 1 pc | |

| 25 | 1 pc | |

| 30 | 1 pc | |

| 40 - 50 | 1 x 2 |

Other Information

- Minimum Order Quantity:10 sq. metre(s)

- Port of Dispatch:Nhava Sheva

- Production Capacity:15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details:Pallets/ Loose/ Customised. Packaging shall ensure smooth and safe transport of materials whether dispatched inland or overseas.

Superior Chemical and Corrosion Resistance

Designed to withstand highly corrosive environments, these PVC sheets provide excellent chemical resistance, ensuring long-term performance in industries such as refineries (DM water plants), power plants, and chemical processing units.

Wide Industrial Usability

Suitable for applications in nuclear power plants, defense (ordinance factories), textile, cement, and paper industries, these sheets offer versatility while meeting stringent industry standards for safety and quality.

FAQs of PVC Sheets:

Q: How are these PVC sheets installed in industrial settings?

A: Typically, these PVC sheets are installed using appropriate mounting techniques that accommodate their smooth internal surfaces and specific diameters. Professional installation ensures secure fitting and optimal performance in demanding environments.Q: What makes these PVC sheets suitable for chemical and nuclear industries?

A: Manufactured from high-quality plastic and PE, these sheets exhibit excellent chemical and corrosion resistance, making them ideal for use in nuclear power plants, chemical industries, and refineries where harsh substances are prevalent.Q: When should I use corrosion-resistant PVC sheets in my facility?

A: Corrosion-resistant PVC sheets are recommended whenever your facility handles aggressive chemicals, demineralized water, or environments with high moisture and temperature fluctuations, ensuring equipment longevity and safety.Q: Where can these PVC sheets be sourced from in India?

A: These PVC sheets are manufactured, supplied, and exported by leading Indian companies specialized in industrial plastics, ensuring reliable delivery and compliance with quality standards.Q: What is the manufacturing process for these smooth internal surface PVC sheets?

A: The sheets are produced using advanced extrusion technology, ensuring a uniform, smooth internal finish and precise diameter control, which supports streamlined fluid transport and reduces build-up within piping systems.Q: How do these PVC sheets benefit facilities in the power and cement industries?

A: Their robust chemical resistance and smooth surface contribute to minimal maintenance, effective material flow, and extended lifespan, making them highly beneficial for critical operations in power and cement plants.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email