HDPE Stub End- Long Neck

Product Details:

- Features Leak proof, High Impact Strength, Durable, UV Resistant

- Usage Pipe Jointing, Pipeline Flange Connections

- Surface Finish Smooth

- Diameter 20 to 630 Millimeter (mm)

- Corrosion Resistant Yes

- Pressure Ratings PN4, PN6, PN8, PN10, PN12.5, PN16

- Shape Stub End

- Click to view more

HDPE Stub End- Long Neck Price And Quantity

- 10 Piece

- 100.0 INR/Piece

HDPE Stub End- Long Neck Product Specifications

- 15000 Tons/year

- Butt Weld

- Up to 16 bar depending on size and grade

- Sizes available from 20 mm to 630 mm OD

- High-Density Polyethylene (HDPE)

- Long Neck Stub End

- 20 to 630 Millimeter (mm)

- Stub End - Long Neck

- Water Supply, Irrigation, Sewage, Chemical Handling

- PE100 / PE80

- Stub End

- Smooth

- Yes

- 20 to 630 Millimeter (mm)

- PN4, PN6, PN8, PN10, PN12.5, PN16

- Leak proof, High Impact Strength, Durable, UV Resistant

- Pipe Jointing, Pipeline Flange Connections

Product Description

We are a well-recognized HDPE Stub End- Long Neck manufacturer, exporter and supplier from India. This is a weld type socket that is used in chemical, petrochemical, and allied industries in piping system.

To fabricate and design this stub end, our workforce use first-rate raw material like HDPE and modern machinery & tools as per industry norms. Checked meticulously on different parameters, this HDPE Stub End- Long Neck is available with us in many sizes and specifications at pocket-friendly prices.

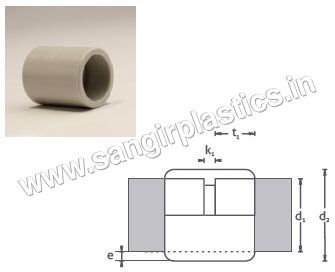

Standard sizing:

|

Code |

d1 |

b |

D2 |

h2 |

L |

SDR17 |

SDR11 |

SDR9 |

SDR7.4 |

|

(A) |

(A) |

(A) |

(A) |

||||||

|

PESE050 |

50 |

61 |

88 |

13 |

85 |

12 |

12 |

12 |

12 |

|

PESE063 |

63 |

75 |

102 |

16 |

99 |

14 |

15 |

17 |

19 |

|

PESE075 |

75 |

89 |

122 |

18 |

111 |

16 |

17 |

18 |

21 |

|

PESE090 |

90 |

105 |

138 |

19 |

121 |

17 |

18 |

20 |

22 |

|

PESE110 |

110 |

125 |

158 |

19 |

135 |

18 |

19 |

22 |

23 |

|

PESE125 |

125 |

132 |

158 |

26 |

147 |

18 |

25 |

28 |

31 |

|

PESE140 |

140 |

155 |

188 |

26 |

156 |

18 |

25 |

29 |

31 |

|

PESE160 |

160 |

175 |

212 |

26 |

160 |

18 |

26 |

29 |

32 |

|

PESE180 |

180 |

180 |

212 |

31 |

169 |

20 |

30 |

34 |

36 |

|

PESE200 |

200 |

232 |

268 |

33 |

192 |

24 |

32 |

36 |

39 |

|

PESE225 |

225 |

235 |

268 |

33 |

183 |

24 |

32 |

36 |

39 |

|

PESE250 |

250 |

285 |

320 |

35 |

205 |

25 |

35 |

38 |

42 |

|

PESE280 |

280 |

291 |

320 |

36 |

206 |

25 |

35 |

38 |

42 |

|

PESE315 |

315 |

335 |

370 |

36 |

226 |

25 |

35 |

38 |

42 |

|

PESE355 |

355 |

373 |

430 |

40 |

245 |

30 |

40 |

45 |

50 |

|

PESE400 |

400 |

427 |

482 |

45 |

270 |

33 |

45 |

50 |

55 |

Weld Type: Socket

Other Information :

- Minimum Order Quantity: 10 Piece(s)

- Production Capacity: 15000 metric tons per year

- Delivery Time: 2-4 weeks

- Packaging Details: Loose, Pallets or customized as per customer requirement.

Durability & Safety Standards

This HDPE Stub End - Long Neck combines superior impact strength and UV resistance, making it ideal for both exposed and buried pipeline applications. Fabricated as per IS 4984 and ISO 4427, each unit is non-toxic and certified food grade, ensuring safe water and chemical transport. Its smooth finish and pressure ratings up to PN16 guarantee reliable, leak-proof performance even in demanding environments.

Flexible Applications & Installation

Engineered for versatility, this stub end supports usages from water supply and irrigation to sewage and chemical handling. Compatible with HDPE pipes and fittings, it is designed for butt welding, ensuring secure, permanent connections. The wide port sizes (20 mm - 630 mm OD) accommodate a range of project requirements, simplifying integration with existing infrastructure.

FAQs of HDPE Stub End- Long Neck:

Q: How is the HDPE Stub End - Long Neck installed in a pipeline system?

A: The HDPE Stub End - Long Neck is designed for butt fusion (butt weld) installation. This process involves heating the ends of both the stub end and the adjoining HDPE pipe, then joining them together to form a seamless, leak-proof connection. Proper alignment and controlled heating are essential for optimal performance.Q: What are the primary uses of the HDPE Stub End - Long Neck?

A: This fitting is commonly used in water supply, irrigation, sewage, and chemical handling systems. It serves as a pipe joint interface, particularly effective for flange connections, making disassembly and maintenance easier in large diameter pipelines.Q: Where can the HDPE Stub End - Long Neck be applied?

A: You can use this stub end in municipal water distribution networks, agricultural irrigation projects, industrial chemical pipelines, and sewage management systems. Its corrosion- and UV-resistant properties allow for both indoor and outdoor installations.Q: What benefits does the HDPE Long Neck Stub End offer compared to traditional materials?

A: Compared to metal or PVC fittings, HDPE Stub Ends provide exceptional impact resistance, chemical inertness, leak-proof joints, and a longer service life. Their non-toxic food-grade material ensures safe transportation of drinking water and chemicals, while UV resistance allows outdoor usage without degradation.Q: When should different pressure ratings (e.g., PN4PN16) be selected?

A: Pressure ratings should be chosen based on the operational pressure requirements of your pipeline. For higher pressure systems, select stub ends with higher PN values (e.g., PN10, PN12.5, PN16). Consult project specifications and local standards to determine the most suitable rating.Q: How does the HDPE Stub End perform in varying temperatures?

A: This stub end operates effectively within a temperature range of -40C to +60C, maintaining flexibility and impact strength in both cold and warm climates, making it suitable for diverse geographical and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free